|

| |

|

|

| |

* VAT and delivery costs not included |

|

|

| |

CRACK MONITORS |

| |

TYPES: |

| |

For measuring the change in cracks in a same plane. |

| |

Displacements in 2 directions. |

| |

>Minimum value 0,5 mm. |

| |

>Minimum value 0,1 mm. |

| |

Displacement in 1 directions. |

| |

>Minimum value 0,1 mm. |

| |

>Minimum value 0,2 mm. |

| |

>Minimum value 0,05 mm. |

| |

>Minimum value 0,02 mm. |

| |

|

| |

For measuring the change in cracks in a different plane. |

| |

Displacements in 3 directions. |

| |

>Minimum value 0,1 mm. |

| |

Displacements in 2 directions. |

| |

>Minimum value 0,5 mm. |

| |

Displacement in 1 directions. |

| |

>Minimum value 0,1 mm. |

| |

|

| |

Small transparent ruler for measuring cracks. |

| |

|

| |

Digital gauges. |

| |

|

| |

Triangular, conical and digital gauges. |

| |

|

| |

Handle magnifiers with reticle. |

| |

|

| |

Vitrometer. |

|

|

|

|

|

|

|

|

|

| |

|

| |

FI100A, FI100A-10, FI100A-50 |

| |

|

|

|

|

|

|

|

FI100AN, FI100AN-10, FI100AN-50

Crack monitor 1 direction, resolution of 0,1 mm. range 0-70mm. Dimensions: body (8x6 cm), rule (17x1cm). Customizable logo for orders above 100 units, no additional cost. Indoor/outdoor use.

|

|

|

|

aaaaaaaaaaaaaaaaa |

|

FI100A

13.95 €

From 1 to 9 Units

In Stock |

|

|

|

|

|

|

aaaaaaaaaaaaa

|

|

FI100AN-10

12.90€

From 10 to 49 Units.

In Stock |

|

|

|

|

|

|

aaaaaaaaaaaaaaa

|

|

FI100AN-50

11.50 €

50 or more Units

Available: 5 days |

|

|

|

|

|

| |

DATA SHEET |

| |

|

- Dimensions: body (8x6 cm), rule (17x1cm)

- Reading accuracy 0,1 mm (vernier scale)

- Monitoring the change in cracks in the same plane.

- They can be fixed in place using double-sided self adhesive or screws (not included).

- White color

- Resistant to bad weather (Doble plastic layer)

- Outdoor/indoor use

|

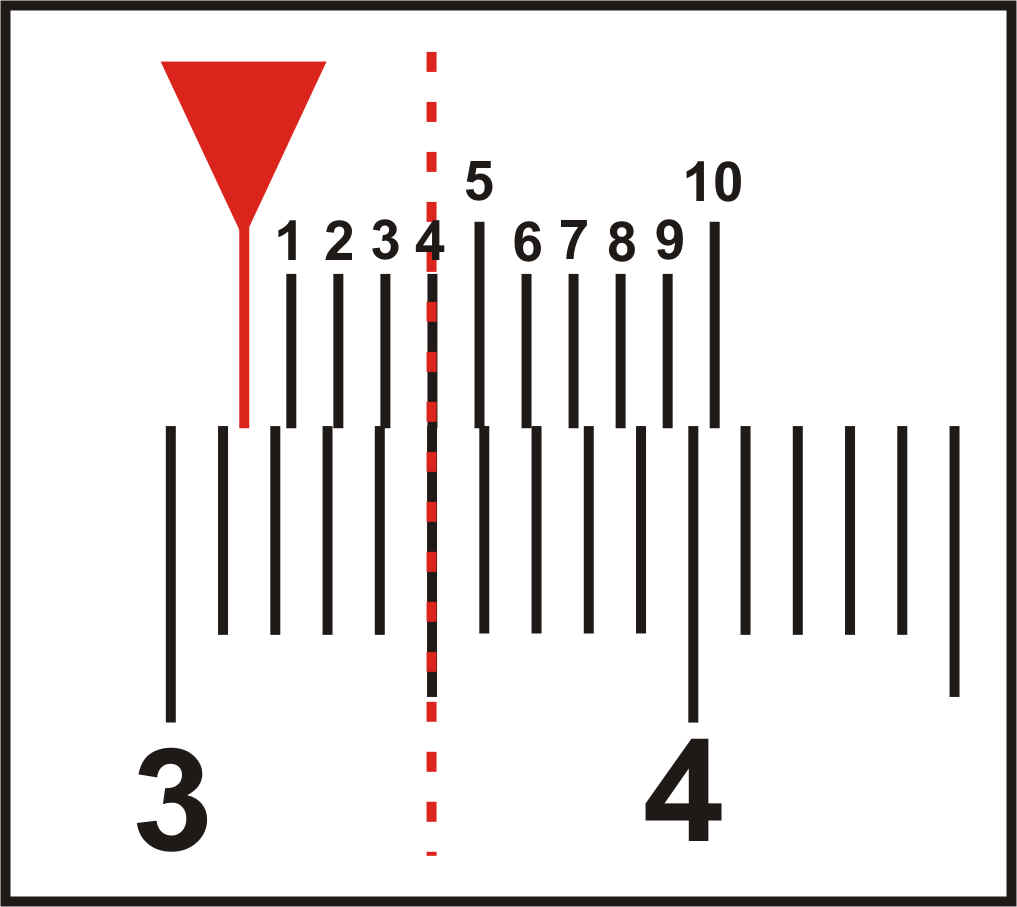

Example of reading the vernier

The upper scale of the crack monitor is graduated from 0 to 30mm, the lower scale moves (10 divisions of the vernier) that corresponds to 9 mm on the measurement scale.

|

|

Example of reading

The pointer of the vernier  is between 31 and 32 mm of the upper scale. is between 31 and 32 mm of the upper scale.

Reading the decimal

Find the line of the vernier (lower scale) that corresponds with a line on the measurement scale (red stitched line). In this case that is 4 (vernier scale).

It means reading is 31,4 mm

|

|

|

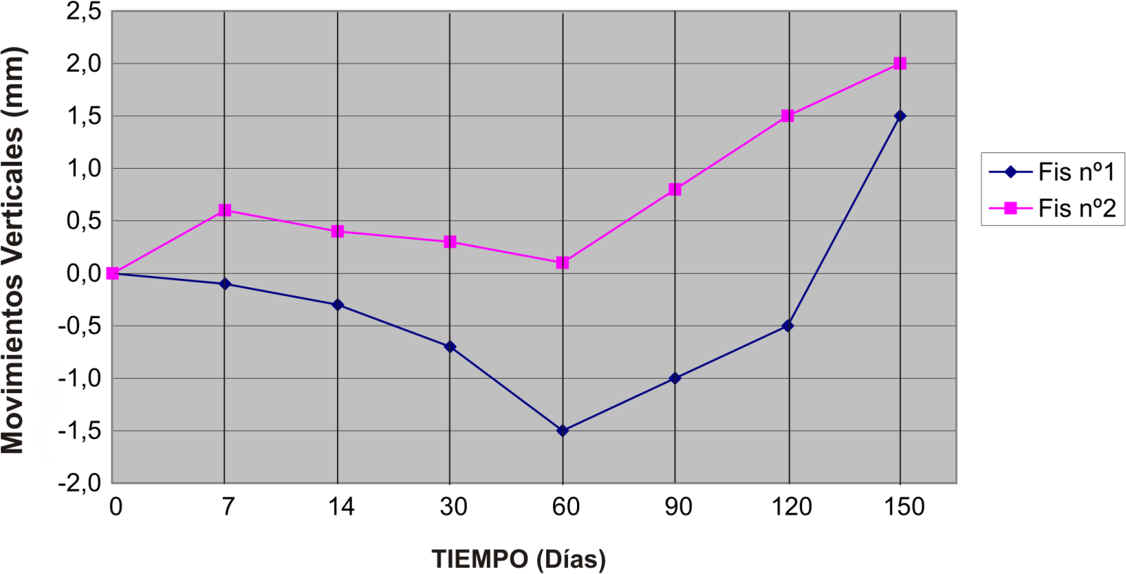

| Using the crack monitor

Once the crack monitors have been placed, they should be checked regulary. We recommend to do it after 7, 14, 30, 60 and 90 days.

With all this measurements a register is taken and reference scales and change graphics are produced. These are essential tools to carry out a diagnosis and evaluate the strength of the damage for monitorising a possible change.

Henceforth, we can determinate the urgency of the repair and the best way to face it and, even, if it could be possible, remove the heart of the matter.

Control of vertical movements

First reading: 1/5/2012

| |

|

|

|

|

|

|

|